Digitalization

Lean manufacturing and “SIQI”management concept (including 5S+, Industrial engineering, Quality control, Informatization )

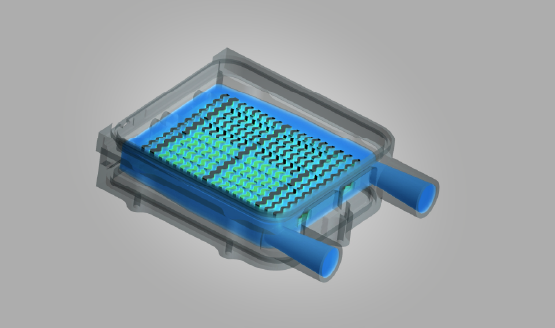

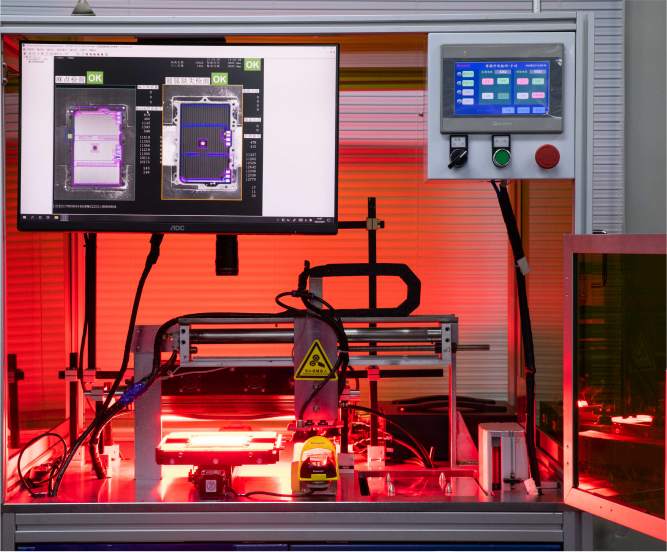

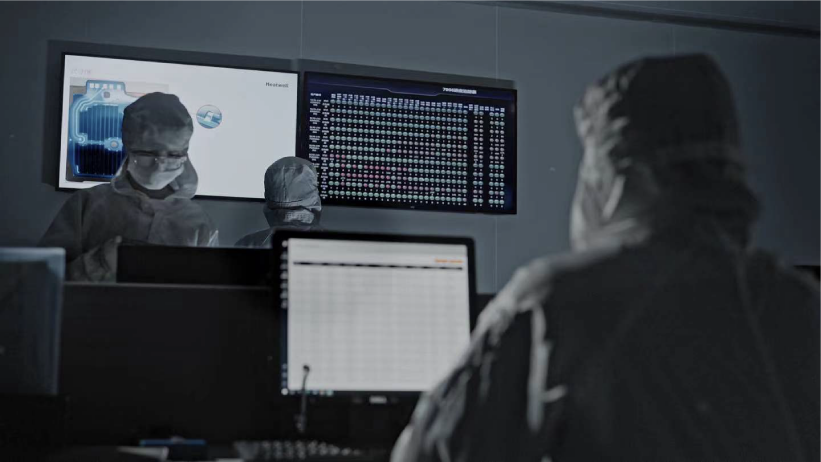

Heatwell establishes an enterprise private cloud and uses PLM, ERP, MES, WMS, SRM, CRM, KANBAN and other management information systems for digital management

Industrial Demonstration 5G Park

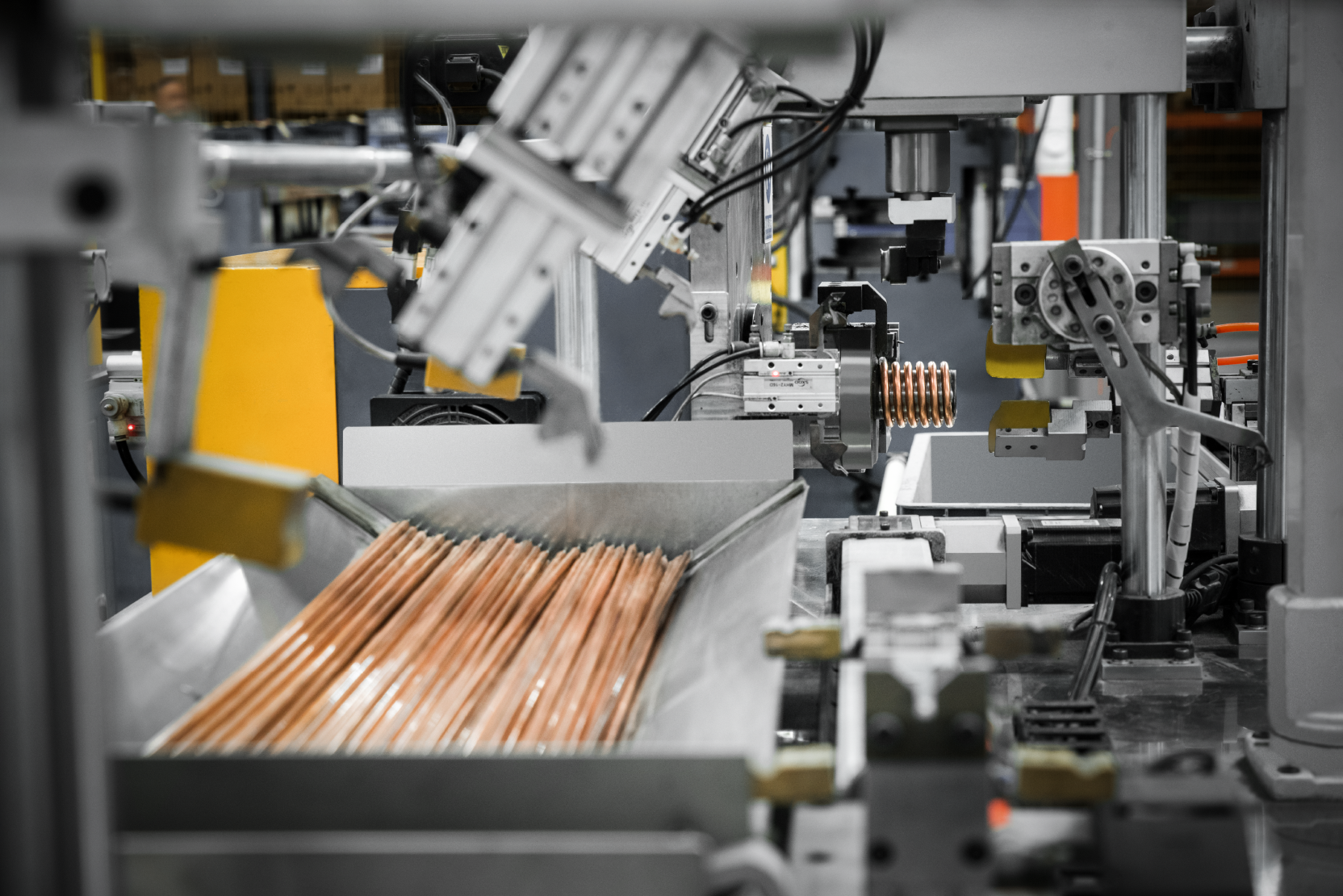

Mass production assembly streamlines and small-scale unit manufacturing capabilities

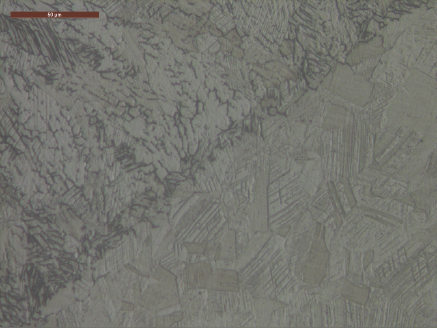

Key materials self-developed and self-made : preparation of magnesium powder for various scenarios, self-made resistance wires and pipes

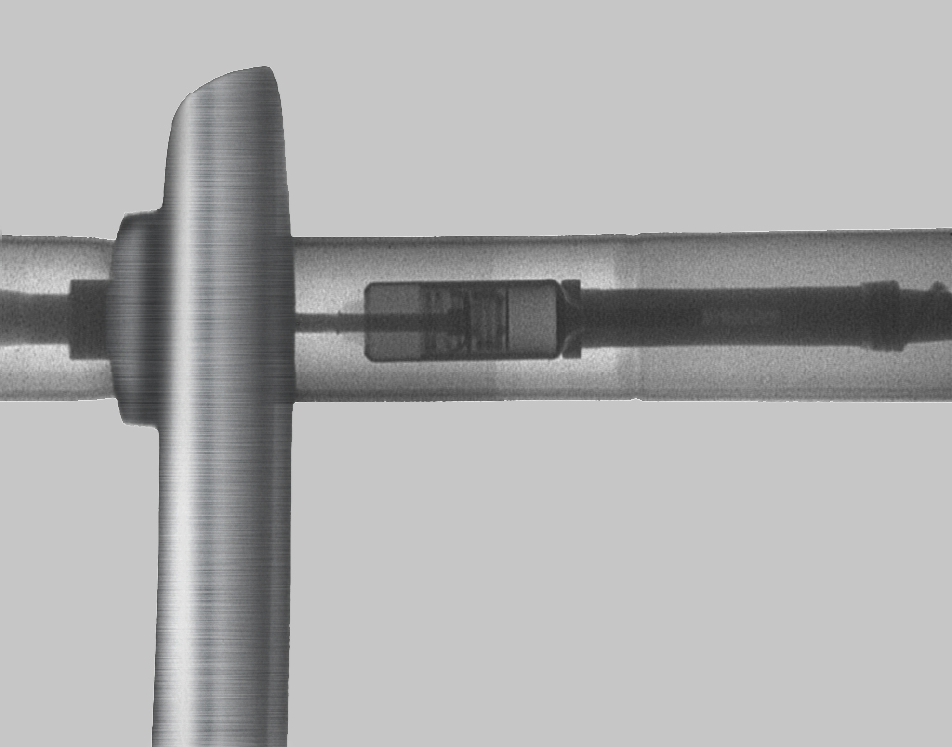

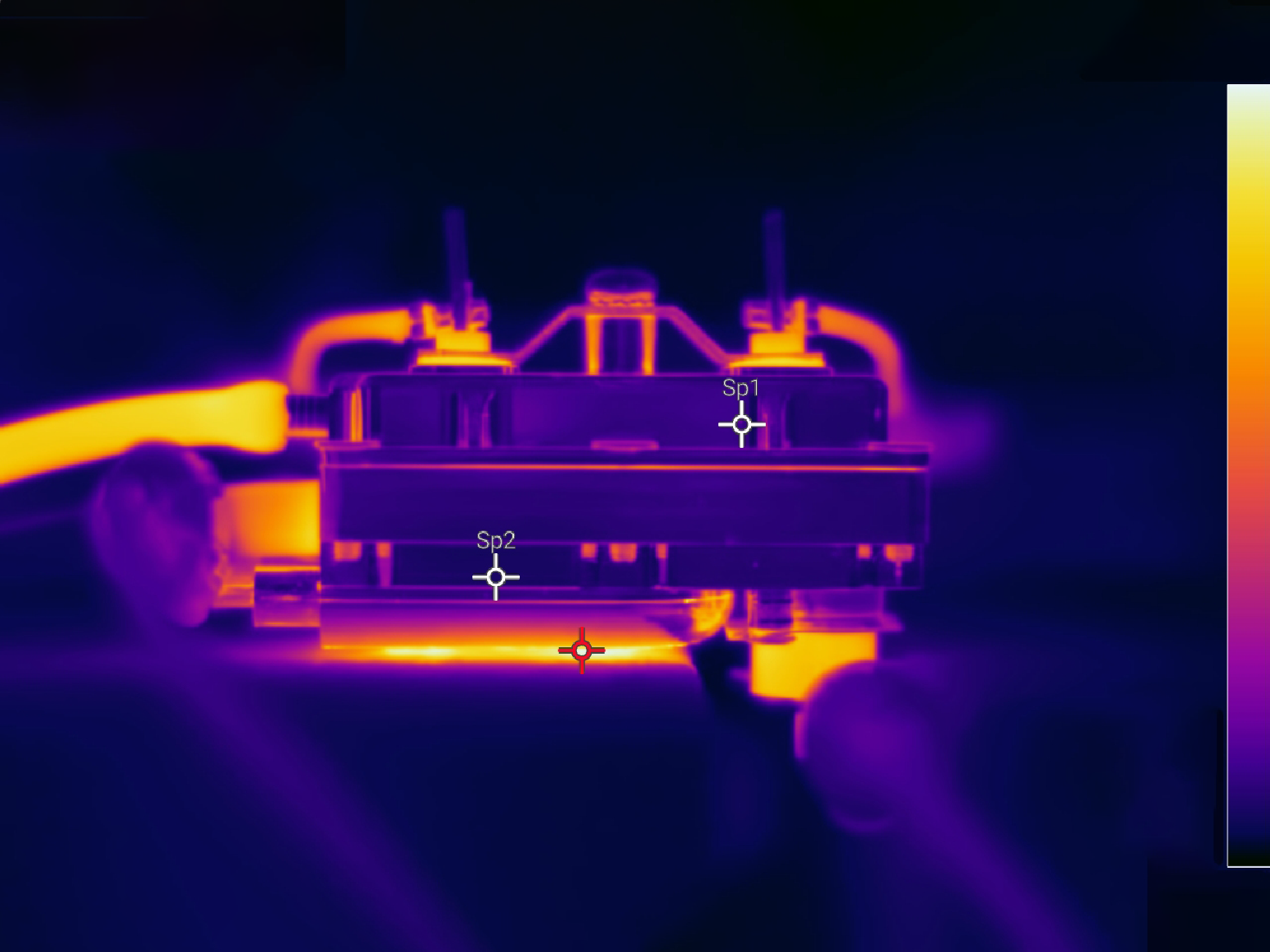

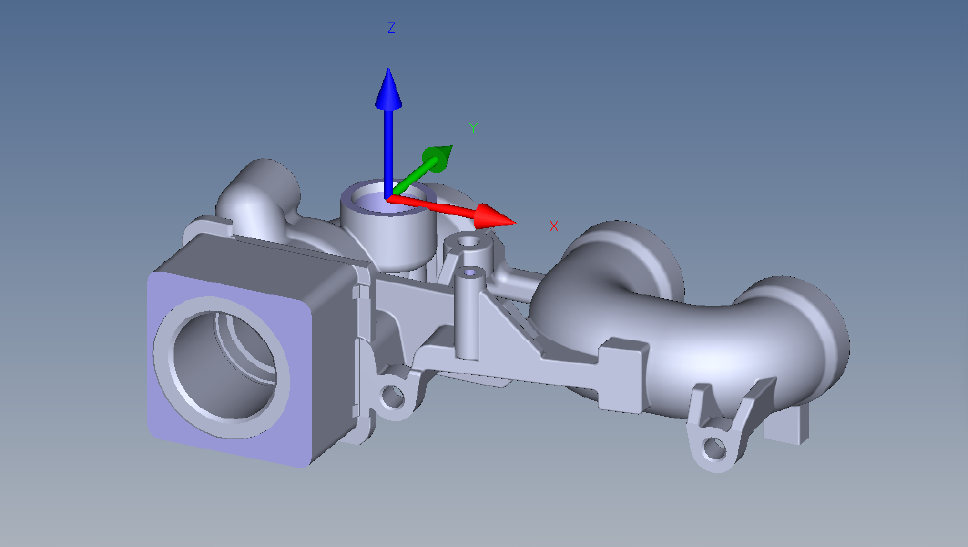

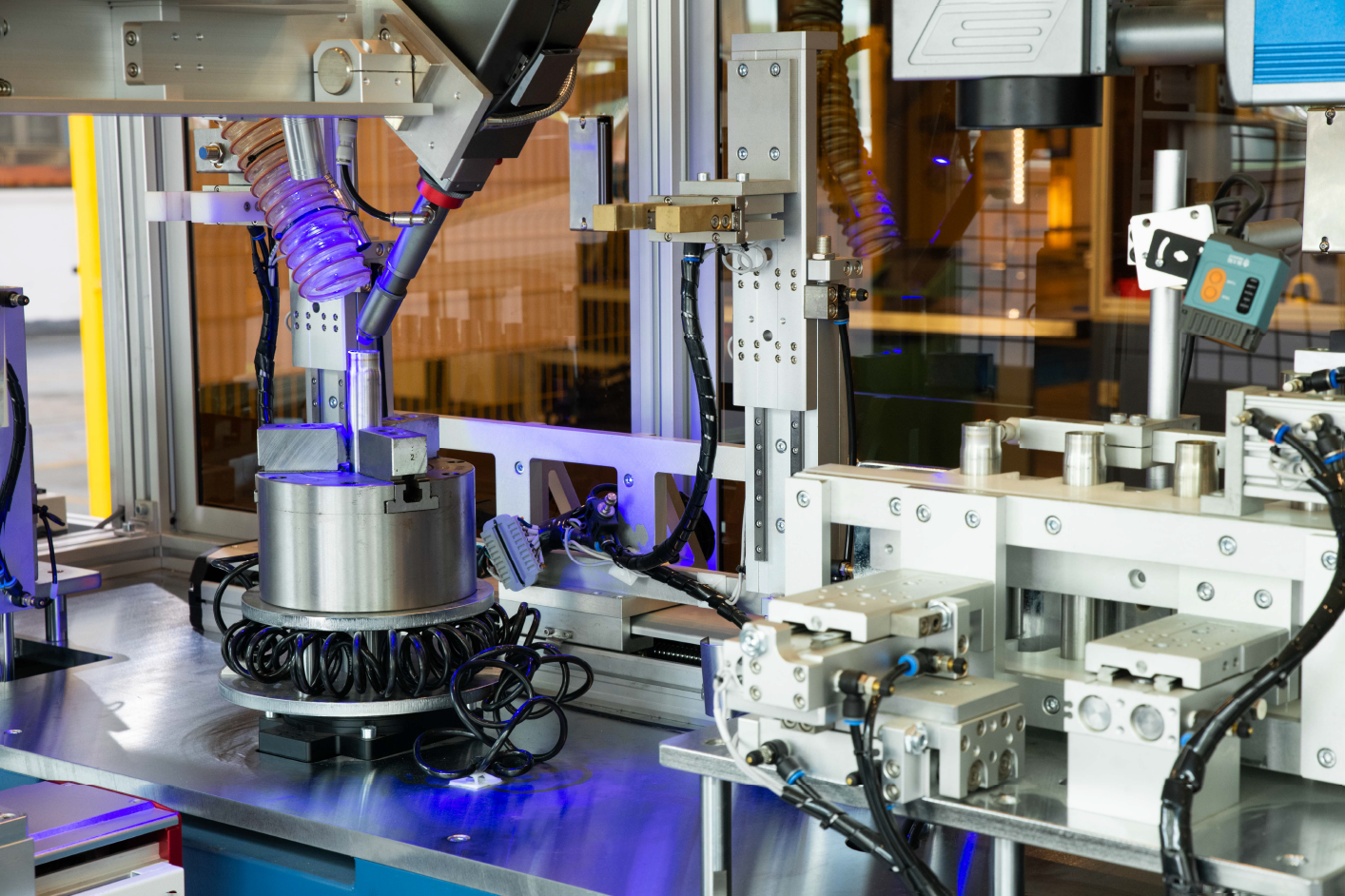

Self-made molds and equipment: self-made molds, special equipment, automation equipment, and experimental and testing equipment

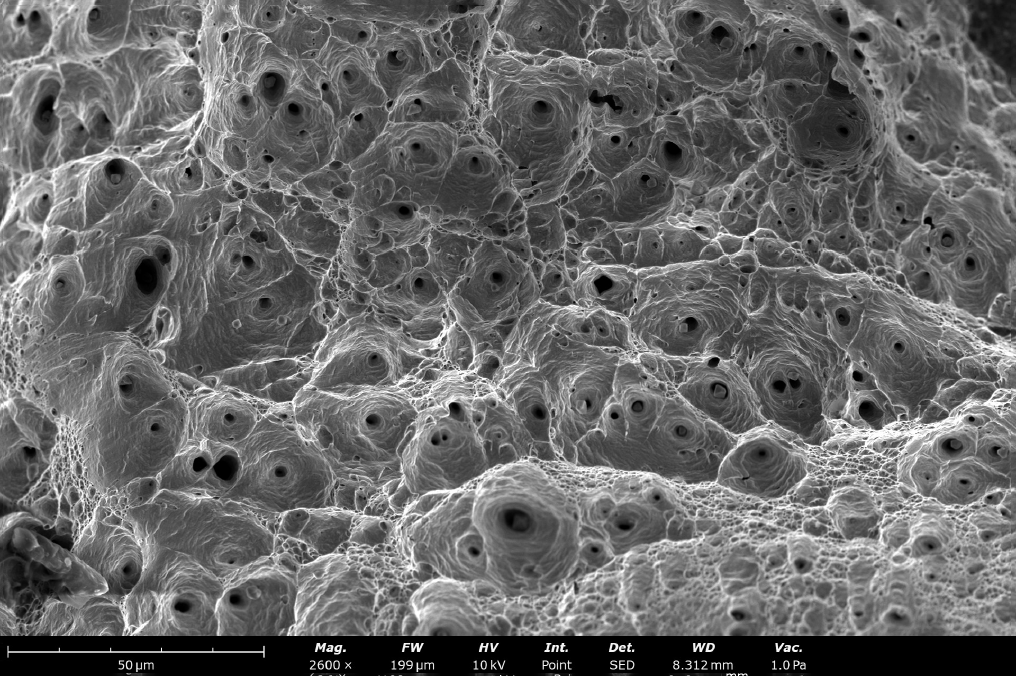

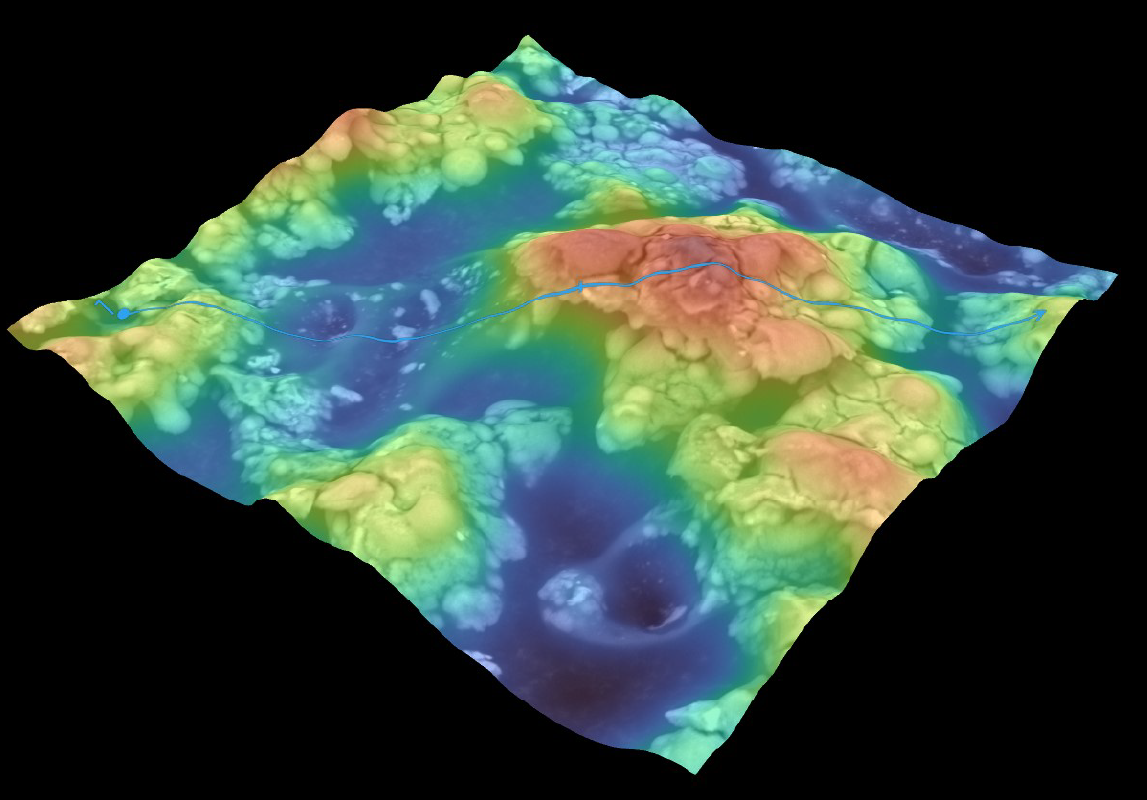

Various manufacturing processes: argon arc welding, laser welding, brazing, vacuum welding; electroplating, nickel infiltration, electrolytic polishing, oxidation, enamel, spray coating; gravity casting, centrifugal casting, low pressure casting, die casting; continuous furnace heat treatment, vacuum heat treatment, local heat treatment

Heatwell has an experienced and comprehensive R&D team, and has created multi-level and multi-specialized R&D platforms. At the same time, it cooperates with many well-known domestic universities and scientific research institutions, utilizing the most cutting-edge technical means and software tools to carry out advanced and efficient R&D activities

Through years of continuous experiments, data analysis and summary, the company has accumulated rich experience in product technology and process technology. We cross-integrate multiple disciplines such as physics, chemistry, materials science, mechanical engineering, and electronic technology to form a comprehensive, systematic and permeable knowledge system to solve new problems and promote innovation.